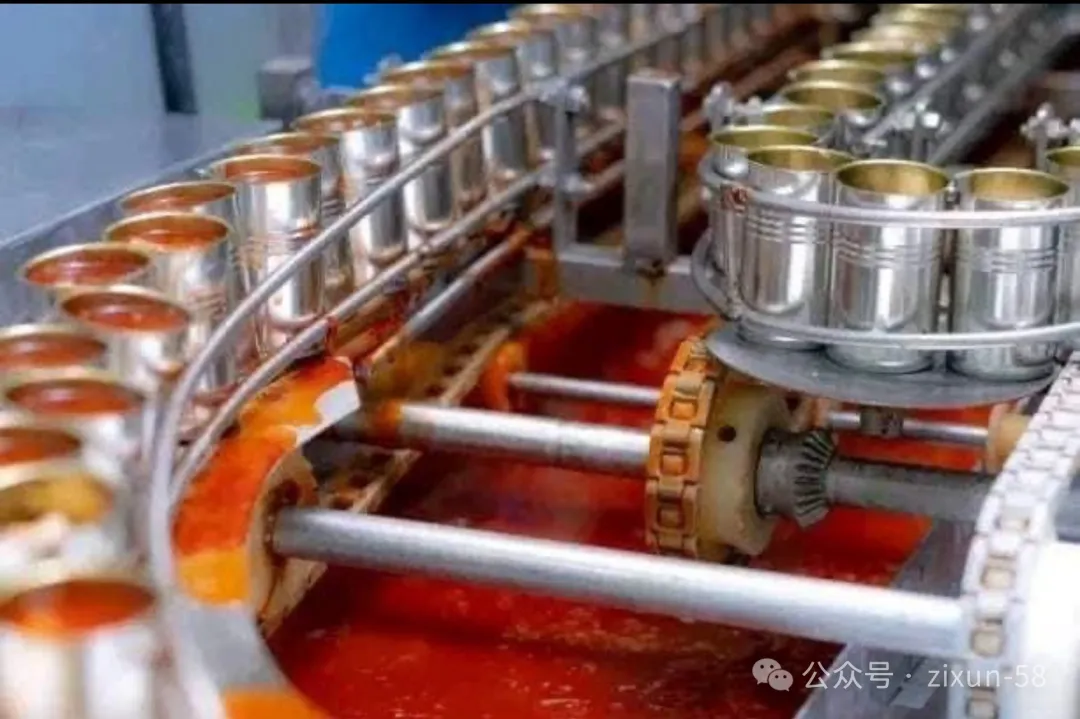

Dangote Group 在尼日利亚卡诺州的 Kadawa 启动了非洲最大的番茄加工厂

Dangote Group在尼日利亚卡诺州的Kadawa启动了非洲最大的番茄加工厂,投资高达2000万美元。预计此举将减少尼日利亚对进口西红柿的依赖,尤其是从中国进口的西红柿,为该国节省约1000万美元的进口成本。除此之外,该工厂还将为当地农民创造就业机会,提高收入水平,加强农业价值链。

Dangote Group has launched Africa's largest tomato processing plant in Kadawa, Kano State, Nigeria, with a whopping $20 million investment. This move is expected to reduce Nigeria's reliance on imported tomatoes, especially from China, saving the country an estimated $10 million in import costs. But that's not all the plant will also create jobs for local farmers, improve income levels, android strengthen the agricultural value chain.

番茄加工厂的主要特点:

Key Features of the Tomato Processing Plant:

年产量:40万吨番茄酱

Annual Production Capacity:400,000 tonnes of tomato paste

温室苗圃:耗资30亿奈拉,旨在养殖3-3.5亿吨杂交番茄幼苗

Greenhouse Nursery: A N3 billion facility designed to process between 300 and 350 million tones of hybrid tomato seedling

本地消费量:大于本地需求,计划每年生产800万吨,而尼日利亚目前的消费量为230万吨每年

Local Consumption: Exceeds local demand, with plans to produce 8 million tonnes annually, compared to Nigeria's current consumption of 2.3 million tons

该举措与尼日利亚提高自给自足、减少贸易逆差和促进可持续经济发展的目标相一致。感谢Dangote Group为尼日利亚的粮食安全和经济增长所做出的贡献!

This initiative aligns with Nigeria's broader goals of enhancing self-sufficiency, reducing the trade deficit, and promoting sustainable economic development. Kudos to Dangote Group for taking a bold step towards Nigeria's food security and economic growth!